Today, an increasing number of experiments with plants and processes are performed in virtual environments instead of expensive and time-consuming full-scale experiments.

At LKAB there has always been a need for computer simulations to understand the best options for designing everything from mining shafts to machines. – As early as in the 1980s, simulations were carried out in research and development and in mining technology at LKAB. The ambition and knowledge have always been there, but the technology was not mature enough at that time. Simple simulations took tremendously long time. Despite that, simulations were used anyway because of the interesting test results that could be captured, says Kjell-Ove Mickelsson, Senior Engineer at LKAB in Malmberget.

“Simulations provide opportunities to test ideas that you cannot or dare not test in reality.“

Kjell-Ove Mickelsson, Senior Engineer at LKAB in Malmberget.

Simulations provide opportunities to test ideas that you cannot or dare not test in reality. By testing the effect of many small changes you can reach an optimal design. That is the essence of using simulations. – There has been tremendous development in this area the latest years. It’s amazing what we can simulate now, even down to a millimeter resolution. At the end of the 90s I did some simulations myself, including fragmentation of pellets, but even at that time it took a very long time. But the idea had started to grow and I started experimenting a bit myself with game engines to see the opportunities, says Kjell-Ove Mickelsson.

“There has been tremendous development in this area the latest years. It’s amazing what we can simulate now, even down to a millimeter resolution.“

Kjell-Ove Mickelsson, Senior Engineer at LKAB in Malmberget.

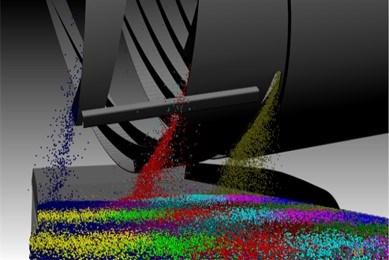

In 2009 LKAB, Algoryx, Optimation AB and Umeå University launched the project GranuX, It aimed at developing an advanced simulation tool for large-scale material flows. – Algoryx was doing granular simulations with vehicles, trucks, tractors and things like that, and at LKAB we wanted to simulate flows in mills and roller drums. We found out that we had about the same visions and challenges. Algoryx had developed an easy-to-use software for 2D drawing with embedded realtime physics simulation, originating from a master thesis project at Umeå University. The GranuX project had the vision of a similar application but in 3D, based on the 3D physics simulation technologies at Algoryx, with sufficient performance and precision to be able to use the results in the industry. This became the goal for the simulation tool to be developed. When Vinnova stepped in as co-financier, the project was established.

“Algoryx was doing granular simulations with vehicles, trucks, tractors and things like that, and at LKAB we wanted to simulate flows in mills and roller drums. We found out that we had about the same visions and challenges.“

Kjell-Ove Mickelsson, Senior Engineer at LKAB in Malmberget.

Since then, this technology has been used in a variety of projects within LKAB’s organization. In Narvik port a new ship loader has been built in Kaj 7. A critical component in the logistics chain is to decrease fragmentation of the pellets. This can be done by minimizing drop heights and increasing the precision of the loading process on to the boats, this to reduce wear and tear as much as possible on both pellets and machines. The rebuilds and changes made so far has been entirely by means of simulations: – Regarding the last chute to the conveyor out to the boats, we simulated all possible different variants of the pellets flow and positioning on the conveyor belt. It is a complicated process, which is critical and has to work. The pellet trajectories must be carefully controlled by the design. Up till today, about three million tonnes have been fed through the system and the transfer solutions that were improved using simulations. And they seem to work well, says Kjell-Ove Mickelsson.

Another example were simulations has been beneficial is in the underground mine in Malmberget, where the skips were limiting the throughput of ore. A mobile ore chute for transferring some of the material onto trucks was needed. Such a transfer solution must be robust, have minimal wear and lead to fast loading of the trucks. Simulations of the suggested solutions were made and presented to the designers, mechanics and drivers which all provided input and identified and highlighted potential problems – for example where rock spillage wear could occur. As a result, the design could be done right from the beginning instead of making modifications after the installation. During the years when the skips were rebuilt, fourteen million tonnes of raw material passed through the mobile ore chute annually and it is still in use.

– It’s thrilling to be a part of these kind of projects, with results that really matters and makes a difference, says Kjell-Ove Mickelsson. – Right now, there is interest from Svappavaara to use simulation as a base for development of pellet outlets, and more projects in Narvik where there are further needs for improvments of critical transfer points.

Original text and photo by per.juntti@lkab.com, translated and published with permission.

About LKAB

Luossavaara-Kiirunavaara AB (publ), which is abbreviated to LKAB, is an international high-tech mining and mineral group that mines and processes Norrbotten’s unique iron ore for the global steel market. LKAB is one of Sweden’s oldest industrial companies and are wholly owned by the Swedish state.

Sustainability is the core of LKAB’s business, and their ambition is to be one of the most innovative, resource-efficient and responsible mining companies in the sector. LKAB manufactures and supplies highly processed iron ore products to the global steel market. The majority of their iron ore products are sold to European steelworks. Other important markets are the Middle East, North Africa, Asia and the USA.

The group had sales of more than SEK 25.9 billion in 2018 and employs about 4200 people in 13 countries. Other group business include industrial minerals, drilling systems, rail transport, rockwork services and property management.

About Algoryx

Algoryx Simulation is a leading provider of software products and services for visual and interactive physics based simulation. The product referred to in the LKAB case is Algoryx Momentum Granular, which integrates Algoryx simulation engine, AGX Dynamics with a both powerful and easy-to-use CAD modeler enabling engineers to simulate both complex material flow and machine dynamics in one unified solution.